What is CLEARSTONE?

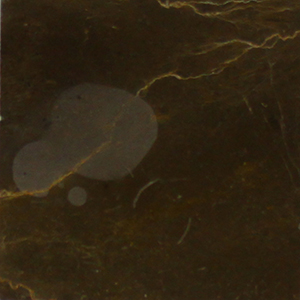

A marble Island coated with Clearstone honed finish.

A specially formulated resin based coating system that is clear and can be applied to many types of natural stones including marble, limestone, sandstone etc.

CLEARSTONE™ is a specially formulated coating that is applied using specifically developed techniques to afford the stones surface outstanding stain, etching and chemical resistance.

Why use a coating system on stone?

The standard way of protecting stone is to apply ‘sealers’. We have not found a sealer that can prevent ‘etching’, or for that matter, fill all the imperfections in the surface of the stone that can harbour bacteria. If you look closely at the natural stone’s surface it is full of open fissures, cavities, cracks and faults that look, from a distance, like dull areas on the surface or a different coloured vein that is a softer material than the main stone.

These imperfections add to the stone’s aesthetic appearance and can be the reason for choosing the stone in the first place.CLEARSTONE puts a barrier over the entire surface like a layer of thin clear liquid glass filling the imperfections leaving a smooth surface that prevents any materials/chemicals from coming in contact with the natural stone’s surface.

What is the difference between staining and etching?

Surface staining is where a chemical has left a coloured mark on the surface. This stain/mark may be sitting on the surface or have penetrated into the stone depending on how porous the stone is. Sealers will buy you some time to remove the offending chemical before the surface is permanently stained. This will vary depending on the sealer, stone and chemical involved, some chemicals can stain in minutes.

Acid EtchingSurface erosion of natural stone. WHAT CAUSES ACID ETCHING? Marble, travertine, limestone and onyx will react to acidic foods (i.e. lemons or tomatoes) and acidic liquids (i.e. some cleaners or acid rain). This reaction will result in a dulling in surface sheen and change in texture, otherwise referred to as “acid etching”.

Acid EtchingSurface erosion of natural stone. WHAT CAUSES ACID ETCHING? Marble, travertine, limestone and onyx will react to acidic foods (i.e. lemons or tomatoes) and acidic liquids (i.e. some cleaners or acid rain). This reaction will result in a dulling in surface sheen and change in texture, otherwise referred to as “acid etching”.Etching is a totally different problem. A lot of problems that are associated with a majority of stone surfaces are that they are actually etched not stained.Marble and Limestone are composed of calcite which is highly sensitive to acids spills which corrodes the surface (etching) thus damaging the polished or honed finish. Even acids in water can affect some stones leaving a white ring from a glass left on a bench top.Etching can appear as a blotch or dull spot, have a lighter coloured (white) bleached appearance, feel rougher, or feel and look as if the surface is pitted. Severe etching can lead to the surface crumbling and flaking.

Some stones like marble and limestone can also be porous and are susceptible to both staining and etching at the same time. Other stones such as sandstone and basalts are not receptive to a high-honed or polished finish due to their open grains. This can make them more susceptible to staining and etching.

Once the surface is etched how can it be restored?

The only way to fix etched stone is to mechanically grind the surface until you get to unaffected stone below the etching. The depth of the grinding will vary depending on the severity the etching and how long it has been allowed to continue as the pitted surface will continue to collect acids.

How do you repair damaged Stone in general?

The stone needs to be sanded/ground deep enough to remove all visible signs of anything that was not part of the original stone. Our Licensed applicator can advise you on this. The amount of surface sanded/grinding will vary depending on the level of damage and the type of stone. The standard process for rejuvenating stone is to surface grind and sand using water from course through to fine diamond disc, requiring several steps depending on the level of shine required. Once this is complete, you are still left with no protection for the stone from etching and staining.

With the CLEARSTONE process the stone can be wet ground and vacuumed dry. Then the coating is applied. Once the coating is cured it is vacuum dry sanded to the finish desired. Then either hand or machine buffed to a gloss if required.

Note: The cost of rejuvenating the stone is built into the CLEARSTONE process. And the stone is now fully protected.

Does the CLEARSTONE coating look ‘plastic’?

No. We went to great lengths to ensure that the finishing process gave a natural stone appearance. Most stone manufacturers can not tell the difference between coated and uncoated marble. You will have the option of either a honed or full gloss finish.

Does stone coated with CLEARSTONE feel different?

The surface is smooth; you do not feel all the imperfections in the stone. The CLEARSTONE coating will cover any recesses, joints, and grout lines.

Does stone coated with CLEARSTONE look any different?

In most cases it does not look any different, but the coating does tend to enhance some stone and bring out the natural characteristics. You will be amazed at the depth it can give to stone. Because it is a coating all fissures cavities and faults will be filled leaving the surface looking more like glass.

Limestone commercial washroom vanity coated with Clearstone.

Where can CLEARSTONE be used?

The CLEARSTONE coating is ideal for both commercial and residential application. The CLEARSTONE coating can be used for bar tops, kitchen tops, vanity tops, furniture, etc.

CLEARSTONE can be either applied prior to, or following, installation of a new surface or can be applied after rejuvenating existing stone tops in just about any application that natural stone is used. At the moment the CLEARSTONE coating is mainly used on counter tops.

How does one clean a CLEARSTONE coated top?

All natural stone, including CLEARSTONE coated tops, should be cleaned only using a neutral cleaner. Neutral cleaners can be purchased at any hardware store.

How impact resistance is Clearstone?

As the CLEARSTONE coating is 1-2 mm thick, and also having extra additives mixed in it to improve the coating performance, it gives protection from both impact and thermal shock (the stone itself does not come in contact at all).

Is CLEARSTONE scratch resistant?

Following the initial curing of the stone coating, the surface attains a hardness of approximately 2 [similar to that of limestone] on a MOH scale [used for stone] of 1 to 10 with the maximum hardness of approximately 4-5 [similar to that of marble] being reached by three months, depending on the local temperatures. Scratches may occur prior to full surface hardening but these can be easily removed.

Can hot pots and pans be placed on stone coated with Clearstone?

Even though one of the additives in our stone protection is an exclusive clear fire retardant, it is not recommended to place hot pans or hot dishes directly on the surface–always use a protective mat.

Can CLEARSTONE be resurfaced?

Yes! The surface can be repolished at any time. If you wish to change the level of gloss it is just a matter of re sanding the surface and polishing to the level required. If in extraordinary circumstances the surface has become heavily scratched it can be recoated with the CLEARSTONE.

Can CLEARSTONE be repaired if chipped?

Yes! Chips can be repaired locally and when repaired you will not see the join in the resin clear coating.

Can CLEARSTONE be applied to granite?

The stone coating has been developed specifically for marble, limestone and sandstone. However, it may be possible to coat some granites but it is recommended that a sample be subjected for trial with our coating. Please contact us for further information.

Why did we develop CLEARSTONE?

We firmly believe that coating the natural stone with a resin composite is the only way to fix 100 per cent the problems associated with stone. This gives the customer a long term solution, without compromising the appearance of the stone and the freedom to enjoy having a natural stone product. See our ‘Chemistry and Stone’ document.

Natural stone being a product of Mother Nature means that each piece has its own individual characteristics and is composed of different composites with varying performances, CLEARSTONE give the stone a high performance even surface. As marble and most natural stones are opulent and bring value to a property they need to be easy maintained while still being liveable.

CLEARSTONE is the complete commercial solution for stone.

CLEARSTONE™ has been developed to turn marble, limestone and sandstone into an elegant WORKING worry free surface.

CLEARSTONE™… the ultimate in stone protection.

How is CLEARSTONE applied?

Only licensed and trained applicators may apply CLEARSTONE. Any surface mounted faucets would be removed. The top is scuffed with a diamond impregnated pad and sand paper. The correct amount of CLEARSTONE is mixed and poured onto the surface. It is allowed to cure overnight. The next day the applicator sands the surface with various grits of sandpaper until the desired honed or polished look is achieved. The application of CLEARSTONE is a very clean process. All applicators use HEPA filter dust collectors to assure quick cleanup. Because CLEARSTONE must cure overnight virtually every application requires a minimum of two days.